LITHIUM-ION FORKLIFT BATTERY : Advancing Efficiency in Your Daily Operations

Lithium-ion (Li-ion) batteries have become a game-changer in the realm of forklift technology, ushering in a new era of efficiency and productivity. Here's why ENEROC chooses Li-ion forklift batteries and the numerous advantages they bring to your operations:

1. Increased Productivity

Li-ion forklift batteries outshine their lead-acid counterparts in terms of charging speed and operational efficiency. Unlike lead-acid batteries, Li-ion batteries require minimal rest time before reuse.

Rapid Charging: Li-ion batteries can achieve a full charge in less than 2 hours, eliminating the need for extended downtime associated with lead-acid batteries.

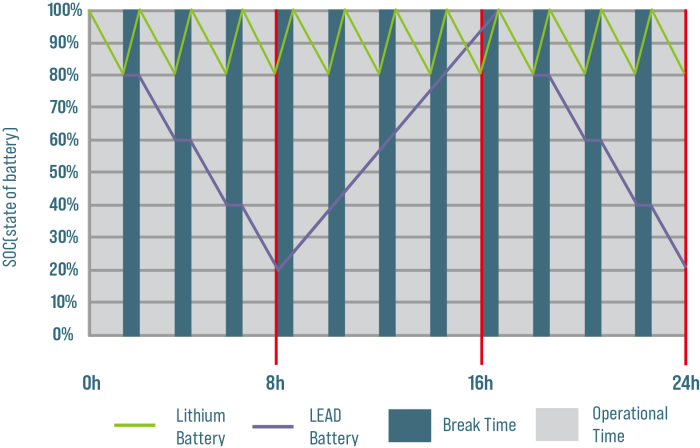

Opportunity Charging: Li-ion batteries support 15–30-minute spurts of charging, known as opportunity charging. This flexibility allows charging during breaks or idle periods, contributing to multi-shift operations.

Extended Run Time: Li-ion batteries offer longer run times on a single charge compared to lead-acid batteries. The flatter discharge curve ensures consistent power delivery even when nearing full discharge.

2. Less Maintenance

Maintenance is a critical aspect of forklift battery performance, and Li-ion batteries excel in this area.

Minimal Maintenance: Unlike lead-acid batteries, Li-ion batteries require little to no maintenance. There's no need for water top-ups, equalizing charging, or cleaning, reducing labor and costs associated with upkeep.

Sealed Cells: Li-ion batteries come equipped with sealed cells, eliminating the need for washing or water addition. This not only streamlines maintenance but also saves space in your facility.

3. Opportunity Charging

Charging flexibility is a key consideration in forklift operations, and Li-ion batteries provide a significant advantage.

Quick Charging Times: Li-ion batteries can be fully charged in as little as 1 to 2 hours, making them eight times faster than lead-acid batteries. This efficiency is achieved without the need for cooling-down periods.

Energy Efficiency: Li-ion batteries store four times more energy and are approximately 30% more energy-efficient than their lead-acid counterparts. This translates to reduced electricity costs and enhanced overall efficiency.

4. Supports Multi-Shift Operations

For operations running multiple shifts, efficient battery charging is paramount.

Shorter Charging Times: Li-ion forklift batteries can be fully charged in 2 hours or less, allowing for quicker turnaround times between shifts.

Opportunity Charging Advantage: The ability to charge during breaks or idle periods supports multi-shift operations with just one Li-ion battery per forklift, eliminating the need for multiple batteries.

5. Better Safety

Safety is a top priority in forklift operations, and Li-ion batteries provide a safer alternative compared to lead-acid batteries.

Sealed Construction: Li-ion batteries are completely sealed, reducing the risk of electrolyte spills, toxic fumes, or sulfation associated with lead-acid batteries.

No PPE Requirement: Unlike lead-acid batteries, Li-ion batteries don't require operators to open the battery compartment for watering. This eliminates the need for personal protective equipment (PPE) and enhances warehouse safety.

Lower Heat Generation: Li-ion batteries operate at a lower temperature, reducing the risk of overheating compared to lead-acid batteries.

6. Less Charging Equipment Required

Li-ion batteries simplify the charging process and reduce infrastructure requirements.

Efficient Charging: Li-ion batteries are easy to charge and require minimal charging equipment compared to lead-acid batteries.

Space-Saving: The absence of the need for multiple batteries per forklift translates to reduced storage space requirements and simplified storage logistics.

7. Higher Return on Investment

In the long run, Li-ion forklift batteries prove to be a sound investment.

Extended Lifespan: Li-ion batteries outlast lead-acid batteries, with a lifespan ranging between 2,000 and 3,000 cycles compared to 1,500 cycles for lead-acid batteries.

ENEROC has established itself as a leader in the lithium-ion forklift battery realm, delivering reliable performance and superior quality. Our batteries serve as the original equipment for renowned forklift brands like Hangcha, Heli, and a range of other international leaders, enabling forklift enterprises to provide user-friendly and efficient material handling solutions. This commitment to excellence solidifies ENEROC's position as a trailblazer in the industry, driving the adoption of advanced lithium-ion technology for enhanced productivity and operational success.

Post time: Jan-04-2024